Table of Contents

Introduction

In the cement truck business, your success hinges on having the right accessories. These essential tools are the backbone of your operations, ensuring efficiency and safety. The business revolves around transporting cement from production facilities to construction sites.

You load cement into specialized trucks equipped with rotating drums to keep it from hardening. From loading to delivery, each accessory plays a crucial role in your daily tasks. So, check out these accessories and assess the importance of each one to your business.

- Concrete Mixer Drum and Tarp Cover

- Water Tank and Pump

- Charging Hopper

- Hoses and Fittings

- Chute Extension

- Concrete Vibrators

- Safety Equipment

- Remote Control Panel

- Mud Flaps and Fenders

- Toolbox

Overview of Cement Truck Business Accessories You Need To Succeed

How to Choose Cement Truck Business Accessories You Need To Succeed

Pros & Cons of Cement Truck Business Accessories

What to Watch Out For

Pro Tips

Recap

>>>MORE: Cement Truck Business Plan

1. Concrete Mixer Drum and Tarp Cover

The concrete mixer drum and tarp cover are vital for the success of your cement truck business. You rely on the sturdy construction of the drum to efficiently mix and transport concrete to your clients. Its rotating design ensures a consistent blend, saving you time and maintaining the quality of your concrete.

Also, the tarp cover primarily protects the concrete in the drum from exposure to various environmental elements (rain, sunlight, wind, dust, debris, and temperature fluctuations) during transport. It helps you maintain the quality and consistency of the concrete, which is fundamental in delivering satisfactory or high-quality concrete to construction sites.

- Durable and long-lasting

- Efficient concrete mixing

- Consistent concrete quality

- Enhanced business productivity

- High initial cost

- Heavy and space-consuming

- Noisy operation with vibration

- Proper maintenance is required

- Position the cement truck properly

- Turn on the truck’s engine

- Engage drum’s rotation slowly

- Add cement, water, and aggregates gradually

- Mix until consistency is uniform

- Deploy the tarp cover over the drum

- Drive to the job site

- Position truck to discharge concrete

- Clean the drum and tarp cover after completion

2. Water Tank and Pump

You need a reliable water tank and a pump to ensure the smooth operation of your cement truck business. The accessory, water tank, helps you supply the necessary moisture to mix the cement properly. Without it, your cement would be unusable. The pump assists you in controlling the water flow precisely, giving you the control you need.

- Efficient water supply system

- Convenient for on-site operations

- Accurate water supply prevents material wastage

- Initial setup cost and space requirement

- Regular maintenance and monitoring

- Possible pump malfunctions

- Place truck near water source

- Connect hose to water tank

- Turn on the pump

- Set desired water flow rate

- Start cement mixing process

- Monitor water supply continuously

- Adjust flow as needed

- Turn off pump upon completion

3. Charging Hopper

Invest in a good charging hopper to enhance your cement truck business’s success. It allows you to efficiently load and dispense cement into the mixer. With this equipment, you save time and improve the overall productivity of your operations. Your customers will appreciate the timely and consistent service, leading to increased satisfaction and repeat business. Additionally, the hopper ensures the precise measurement of materials, reducing waste and operational costs.

- Efficient material loading

- Enhanced productivity and speed

- Accurate material measurement

- Reduced operational costs

- Regular maintenance required

- Limited mobility on-site

- Potential for material blockages

- Consistent power source

- Position the hopper near mixer chute

- Ensure power source connection

- Open hopper discharge gate

- Load materials evenly into hopper

- Monitor material flow consistency

- Adjust gate as needed for flow

- Close gate when loading is complete

- Disconnect power source safely

4. Hoses and Fittings

You can’t run your cement truck business without reliable hoses and fittings. You need them for the smooth and efficient transport of cement. Proper hoses and fittings ensure that the cement flows seamlessly from the truck’s mixing drum to the construction site through the discharge chute, preventing costly delays caused by leaks or malfunctions. To maintain a stellar reputation and meet deadlines, invest in high-quality hoses and fittings that you can depend on.

- Consistent workflow and on-time deliveries

- Lower maintenance expenses

- Enhanced operational efficiency

- Susceptible to wear and tear

- Regular inspection is required

- Certain issues such as compatibility with equipment

- Inspect hoses for damage and leaks

- Connect hoses to the mixing drum securely

- Ensure fittings are tight

- Start cement flow gradually and monitor flow rate

- Adjust pressure as needed

- Cease flow when done and detach hoses carefully

- Drain residual cement and clean

- Inspect for wear and tear

5. Chute Extension

You need the chute extension for your cement truck business to direct the flow of concrete efficiently and precisely into various locations on the construction site. With this accessory, you improve your control, minimize spillage, and enhance productivity. Your clients will appreciate your precision and reliability, leading to a solid reputation in the industry.

- Efficient concrete distribution

- Increased reach on-site

- Versatile pouring capabilities

- Enhanced job site safety

- On-site operators require essential skills and training

- Potential maintenance expenses

- Limited access in tight spaces

- Mount the chute extension on the hoses and secure it firmly

- Extend it to reach construction areas

- Direct the cement flow accurately

- Pour concrete with precision to where it’s needed

- Minimize waste or spillage and improve efficiency

- Ensure safety with robust locking mechanism

- Clean after use and perform routine maintenance for reliability

>>>PRO TIPS: Is Cement Truck Good Business?

6. Concrete Vibrators

Concrete vibrators are essential tools for your cement truck business. The vibrators ensure the concrete mix you transport remains properly mixed, preventing separation and maintaining quality. You use them to eliminate air bubbles, improving the structural integrity of your poured concrete. Without these tools, your concrete may not compact properly, reducing its strength and durability.

- Maintains concrete quality or consistency

- Enhances concrete strength

- Reduces air pockets

- Speeds up construction projects

- Generates noise during operation

- Requires power source

- Demands skilled operator

- Causes hand-arm vibration

- Position the concrete vibrators correctly

- Turn on the power source

- Insert the vibrators into the concrete

- Begin with slow, shallow insertion

- Increase depth and vibration time gradually

- Move the vibrator vertically and horizontally

- Watch for air bubbles to escape

- Maintain consistent vibration across the area

- Withdraw the vibrator gradually and confirm even distribution

- Repeat for entire load if needed

- Turn off the vibrator

- Clean and store the equipment properly

7. Safety Equipment

To ensure the success of your cement truck business, you must prioritize safety equipment like reliable backup cameras, safety cones and barriers, durable hard hats, gloves, and high-quality reflective vests for your team. By prioritizing these safety essentials, you not only comply with regulations but also create a secure work environment, minimizing accidents and downtime.

- Enhanced safety for on-site workers

- Low accident risks

- Compliance with safety regulations

- Initial cost of purchase

- Uncomfortable or bulky to wear

- Limited mobility in some cases

- Wear reflective vests for high visibility on-site especially during night shifts

- Don hard hats to safeguard against falling debris

- Utilize backup cameras to avoid accidents when reversing

- Place safety cones around the truck to mark work zones

- Set up barriers to block off work areas

- Follow safety guidelines at all times

- Store equipment properly when not in use

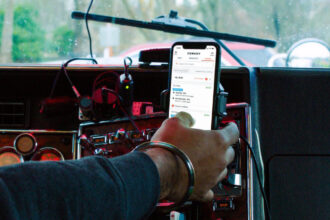

8. Remote Control Panel

With the remote control panel, you manage your cement truck’s functions efficiently. You can monitor and control the mixing process or drum rotation, ensuring the right consistency of concrete. You also have real-time data on fuel consumption, helping you optimize costs. In emergencies, the control panel lets you shut down the truck immediately, ensuring safety.

- Efficient operation control

- Real-time data monitoring

- Enhanced safety features

- Potential technical glitches

- Initial setup complexity

- Essential training required for operators

- Turn on the Remote Control Panel

- Select the mixing mode required

- Set the desired RPM speed

- Monitor concrete consistency visually

- Adjust water flow accordingly if needed

- Observe real-time data on the screen

- Check fuel consumption periodically

- React to any alarms promptly

- Shut down safely after use

9. Mud Flaps and Fenders

Equip your cement truck with mud flaps and fenders to prevent throwing debris, mud, and water on the road and staining its tires and body while in motion. Without them, you may face frequent damage, downtime, and repair costs that eat into your profits. Properly fitted mud flaps and fenders also ensure you stay compliant with road safety regulations, avoiding fines that can hurt your bottom line.

- Compliance with regulations

- Extended vehicle lifespan

- Reduced maintenance costs

- Initial installation expense

- Added weight to vehicle

- Limited style options and may be aesthetically unpleasing

- Position the mud flaps correctly

- Attach them to mounting brackets securely

- Ensure proper alignment and clearance

- Tighten fasteners with appropriate tools

- Make sure the fenders cover tires adequately

- Conduct a test drive for stability

- Make adjustments if necessary

- Double-check for secure attachment points

10. Toolbox

The toolbox plays a crucial role in ensuring your cement truck business thrives. It contains essential accessories like wrenches, pliers, spare parts, and safety gear. With these tools, you can quickly fix any unexpected breakdowns, minimize downtime, and keep your fleet running smoothly. You also ensure the safety of your drivers, showing your commitment to excellence in service.

- Enhances drivers’ productivity

- Streamlines equipment maintenance

- Improves truck lifespan

- Initial cost can be high

- Specific training for use

- Certain risks such as theft and misplacement

- Use wrenches to tighten loose truck components securely

- Cut or manipulate wire and rebar with pliers

- Replace worn or damaged truck parts with spare parts in the toolbox

- Protect workers during maintenance and repairs with the safety gear

- Use sealant or adhesive to seal joints in truck’s components, such as the mixer drum or chute, to prevent leaks

- Tighten screws and fasteners effectively with screwdrivers

Overview of Cement Truck Business Accessories You Need To Succeed

In the cement truck business, accessories such as mixers, tarp covers, hoses, vibrators, water pump, charging hoppers, and chutes are crucial to your success. These tools are not just helpful but essential. Don’t forget the safety equipment, like gloves and hard hats, to protect your crew. Maintenance tools are equally important to keep your trucks running smoothly.

How to Choose Cement Truck Business Accessories You Need To Succeed

To select the right tools for your cement truck business:

- Evaluate your specific truck requirements

- Research reliable suppliers for essential accessories

- Prioritize quality over cost for longevity

- Consider accessories that enhance safety measures and meet industry regulations

- Opt for accessories compatible with your trucks

>>>GET SMARTER: Cement Truck Business: Should I Set Up As A C Corp?

Pros & Cons of Cement Truck Business Accessories

Pros

- Enhance overall operational efficiency

- Improve workers safety and comfort

- Extend equipment lifespan and reliability

- Boost productivity, capacity, and brand image

Cons

- Need substantial capital for purchase

- Require regular maintenance and upkeep

- Add weight and complexity

- Involve compatibility, theft or damage issues

What to Watch Out For

While you purchase your cement truck business accessories, watch out for:

- Inferior-quality as it may hinder performance

- Incompatible tools causing operational issues

- Unreliable suppliers leading to production delays

- Outdated tech

- Complex equipment requiring extensive training

Pro Tips

Get high-quality accessories for your cement truck business with these pro tips:

- Seek expert advice if uncertain

- Research customer reviews for insights

- Compare prices from multiple suppliers

- Plan for future scalability needs

Recap

To flourish in your cement truck business, you need essential accessories that maintain efficiency, increase productivity, optimize profitability, and ensure safety.